| Previous Page | Table of Contents | Next Page |

2. GULLET CRACKS OR GRINDER BURNING

There is no substitute for a well designed, properly maintained and operated band saw sharpener when it comes to eliminating gullet cracks.

Many things can cause gullet cracks besides the band saw sharpener. However, the grinder should be inspected if gullet cracks are experienced.

- Look at your grinding wheel speed. Most grinding wheels are designed to work best at approximately 5500 surface feet per minute (1677 surface meters per minute). See wheel speed chart.

- Match the grit and hardness of the wheel to the work. Generally, a 36 to 46 grit wheel is preferred in a medium hardness. A harder wheel holds its shape longer and grinds more saws. However, it is more susceptible to saw burning and gullet cracks.

Consult with a local grinding wheel vendor as to what types and grades of wheels are used with success in your area.

- Reduce the number of teeth ground per minute to allow the grinding wheel time to remove saw steel without burning.

The quality of any grinding job is primarily a function of the number of sharp points contacting the work piece: the more sharp points, the better the grind. The two simplest and cheapest ways to accomplish this are to slow the grinder down (fewer teeth per minute) and/or speeding up the grinding wheel (without exceeding the manufacturer’s recommendations for maximum wheel speed).

- Use two operations to dress the grinding wheel.

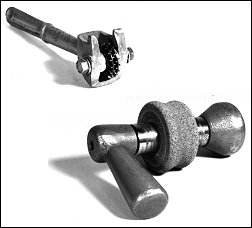

- Dress to shape using a wheel or diamond point See ShapeUp Wheel Dresser

- "Open" to expose sharp cutters using a star-type wheel dresser

- Reduce the stock removal rate. Attempting to remove too much material with each pass can lead to burning and cracks.

- Allowing the sharpener to continue to cycle repeatedly without removing material will "glaze" both the saw and the grinding wheel, resulting in cracks.

- Check the depth stop. The cams are designed to gently slow the descent of the wheel into the bottom of the gullet. The sudden stop against the depth stop can lead to burning and cracks.

- Check the cams and cam follower bearings for wear.

- Look for vibration. The source of the vibration can be an out of balance grinding wheel, bent arbor, worn belt, worn bearings, worn grinding wheel motor or action motor. The vibration can be internal (inside the grinder) or external to the machine.

- Look for "binding" or erratic action caused by the saw support system.

| Previous Page | Table of Contents | Next Page |