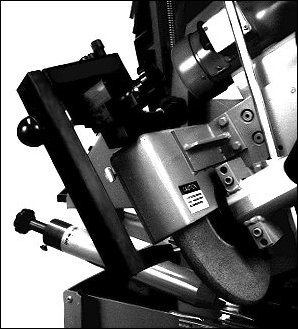

| "Trues" the

Grinding Wheel |

The ShapeUp maintains the wheel rim concentric to the grinding

wheel arbor. The wheel grinds with the entire periphery for faster stock removal,

better finish and less vibration.

|

|

| Same Gullet Shape

Every Sharpening |

The wheel is shaped exactly the same every time, so saw after saw

is ground exactly the same. Full sized wheels are shaped the same as worn wheels. The

night shift will shape the wheel exactly the same as the day shift. The newest filer will

be able to shape the wheel exactly to the head filer’s specs.

|

|

| Saves Time and

Reduces Grinding Expenses |

Saws can be

sharpened in less time with a wheel that has been shaped and trued with a ShapeUp.

Grinding wheels and saws both last longer. Expect up to 1/3 more resharpenings from

every Cobalt Chromium Alloy tipping or swaging. Cobalt Chromium Alloy expenses may be reduced by 25%.

|

|

| Makes for a Cleaner,

Safer Work Area |

Only a thin layer of abrasive (about .001" or .025 mm) is

dressed away with each pass of the diamond. Less dust is released into the filing room for

a safer, cleaner work area. The resinoid ceramic wheels from Armstrong seem to give the

best results.

|

|

| Versatile Performance |

Both metric and American wheel sizes can be shaped with the

Armstrong ShapeUp. No cams or templates are required. The shape can be changed and then

"locked in," so different shapes and different wheel thicknesses can be used.

Even frost notches can be added later with a diamond dressing tool.

|

|

| To Order |

Specify model number and hand of the Armstrong sharpener. Each

ShapeUp comes complete with a wheel shaper, replaceable diamond point, heavy-duty wheel

guard and installation and operating instructions in both video and printed formats. A

dial indicator and straight edge are helpful for proper installation. A star-type

dresser is recommended for "sharpening" or "opening" the wheel after

shaping and truing.

For more information on the Armstrong

ShapeUp grinding wheel truing and shaping system, contact Armstrong or your local Stocking

Distributor/Service Center today. |

| Actual units shipped will be

the latest design which may vary from illustration. |