| Previous Page | Table of Contents | Next Page |

Grinding Variable Tooth Pitch and Depth Saws

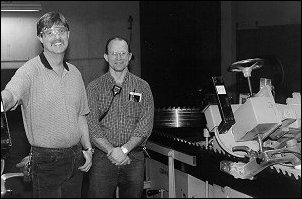

- Mike Gish (left) and Head Filer Mike Neveau of Willamette Industries with the No. 4 VPD Sharpener. The Dalles, Oregon sawmill has increased the feed rate of their horizontal resaw by more than 30% since they introduced VPD technology.

The special VPD No. 4 Sharpener uses cams with three, four, or five lobes so each gullet can be sized to match the tooth spacing. Saw teeth are strong and easier to maintain when the gullet depths are nearly proportional to the tooth pitch. It is possible to sharpen variable pitch saws with a conventional sharpener and single lobe cams. But these saws tend to lose the backs of the shortest teeth as the saws are resharpened.

Sawmills have the option of ordering:

- A brand new No. 4 sharpener with the VPD option installed

- A factory rebuilt sharpener with the VPD option installed

- A VPD kit that can be installed in an all steel-welded frame No. 4 Sharpener made since 1973.

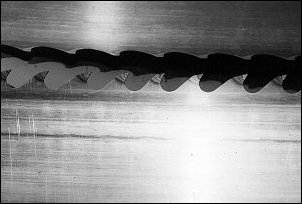

Filers now are verifying the advantages of VPD saw teeth. Feed speeds may be increased. Target sizes and kerfs may be reduced. Unevenly spaced saw teeth can reduce harmonic vibration that causes "washboard" in band saws.

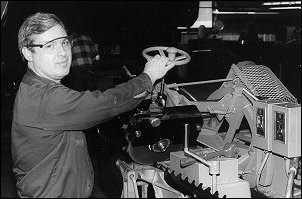

- John Werner maintains the VPD saws at Stimson Lumber's Forest Grove, Oregon sawmill.

Filers have had the most success with a 5-tooth pattern of variable pitch and depth teeth. This pattern has the longest pitch tooth entering the cut first, followed by the second longest tooth, and then the third longest tooth. The two shortest teeth in the pattern are repeated. This is called a segment. The length of the segment is multiplied to make the length of the saw. The tooth pattern should be designed for the best saw performance and ease of grinding.

Willamette Industries’ Dallas, Oregon sawmill agreed to be a test site for one of the first VPD Sharpeners built. Head Filer Mike Neveau reports they have increased the feed rate of their horizontal resaw by more than 30% since they introduced VPD in October. "We are running a 3-tooth pattern and the results are much better than expected" said Mike. "We are converting to a 5-tooth pattern and are expecting even better results."

Ken Brown at Stimson Lumber in Forest Grove, Oregon has been using variable pitch on all his band saws for more than two years and has been using VPD on one of his bandmills for four months. "With the installation of the VPD conversion kit, we are able to maintain a full profile on our saw teeth where we were having difficulty before" said Ken. Stimson started with a 4-tooth pattern and will convert to a 5-tooth pattern after some further improvements at the mill.

Fred Oleson of Oleson Saw Technology likes what he sees with VPD technology. "VPD has been a successful adventure for us. We have a VPD sharpener at our shop in Westbrook, Maine where we are taking care of saws for one hardwood and one softwood mill. The VPD machine and the saws coming off of it are performing exceptionally well. We are proving the results we expected before we started up this program. Feed speeds are increased, washboard has been reduced or eliminated, and the VPD saws cut quieter and smoother than standard saws. Our customers are very happy with results."

Fred continues: "We have customers who have run both VP and VPD saws. The VPD saws outperform the VP saws and they are easier to maintain. With VP, we have seen problems with the tooth shape changing. We don’t see that at all with VPD. Obviously it is an investment for a mill to buy into the program; to purchase a new or upgrade an existing sharpener and purchase all new saws and throw out the standard saws they are using now, but it will prove to be worthwhile."

- Unevenly spaced saw teeth can reduce harmonic vibration that causes "washboard" in band saws.

Fred’s customer, RAM Forest Products also has a VPD Sharpener at their hardwood mill in Shinglehouse, Pennsylvania. "RAM has been very successful with their VPD program" said Fred. "In the past, they experienced a lot of washboard on the boards from the resaw. With VPD, they have substantially increased their feed rates and reduced their washboard considerably."

A VPD upgrade for No. 6 Sharpeners is expected to be available in the summer of 1998. Check with Armstrong or your authorized Armstrong distributor for information on VPD technology.

| Previous Page | Table of Contents | Next Page |