| Previous Page | Table of Contents | Next Page |

Stellite on Circle Saws Provides Major Benefits to Willamina Lumber

Willamina made the commitment to change from carbide to Stellite in mid-1991 and purchased an Armstrong AUTOTIP machine. "I’d be lying if I said I wasn’t afraid of the new technology," said Al. "But our research showed that we could make our jobs much easier, so we dove right in." Their results have been everything they were hoping for and then some. "Obviously our production rate has gone up quite a bit. We are also producing better quality lumber and sawing more accurately. Plate thickness and kerf for our double arbor edger saws is down 17%."

Al continues, "For management, the reduction in kerf and target size translated to real dollar savings as a result of the wood fiber recovery. But the biggest benefit for me and my staff has been the labor savings. On a normal day we handle about 135 saws. If there are any problems our work load goes up significantly. Carbide saws are so labor intensive that we were hard pressed to keep up. Since going to Stellite, the saws are much easier to maintain. Our tip loss is virtually zero and, because the saws run so much better, our time spent benching, etc. is way down. Our payback on the Autotip was considerably less than a year."

Al’s staff consists of benchmen Darold Rich and John Ridgeway, and apprentice Johnny Vollman. The machine centers that Al and his staff are responsible for are a slat bed drive Shurman 12" double arbor edger with 38 saws; a Newnes 2" board edger running 4 saws; an optimized single arbor gang with 13 saws and an optimized board edger with 4 saws.

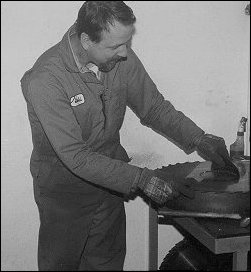

- Benchmen Darold Rich (left) and John Vollman (right) level a couple of the 130+ saws that come trough the filing room every day. Since going to Stellite, the saws run better and benching time is down.

Al and his staff chose Stellite tips that are .150" wide x .240" long for all their saws. This gives them a tip that is long and thick for strength and stability and minimizes the amount of side grinding they have to do. After they are tipped, the saws are put on the hand gummer to rough grind the tops off the tips. "We do this just to save wear on the 120 grit ceramic grinding wheels we use to profile our saws," says Al. The saws are profiled on a No. 25 Armstrong circle saw grinder that has been modified with an air gate and a tooth counter. It takes two passes to get the saw sharp and ready to go on to the TrueSizer dual side grinder where a single pass has the saw ready to go out to the mill. "We get about 10 regrinds on each saw before we have to retip," says Al. "Our saws last us about 10 months before they are too small to use."

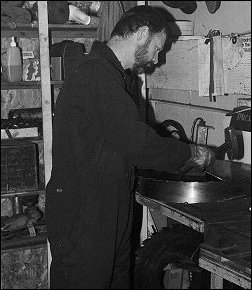

- Lead circle saw filer Al Reznicsek profiles a saw on the No. 25 Armstrong sharpener prior to sending it on to the Armstrong TrueSizer for side grinding.

The Hampton family purchased the Willamina mill in 1942. Although retired, John Hampton remains actively involved in operations at the home office while turning over strategic planning to company C.E.O. Ron Parker and the day-to-day operations to mill manager Tim Hart.

Al has been in the sawmilling business for 45 years. He has been at this Willamina mill for 37 of those years, 27 in the filing room. He is justifiably proud of the fact that his entire filing room staff has come from within the organization and have all been trained by him. It is Al’s plan to retire in April 1999 and spend time doing the things he enjoys best; spending time with his family, fishing, hunting, golfing and bowling. When asked if he had any words of advice for filers that are thinking of venturing into a Stellite program, Al said "Go for it! The results are there and the work load is so much less. As I said, I was scared at first but now I wouldn’t have it any other way."

The Saw Engineer commends Willamina Lumber and their filing room staff for their success. We also extend special thanks to Al Reznicsek for his help in preparing this article and wish him the very best when his retirement day does come.

| Previous Page | Table of Contents | Next Page |