| Previous Page | Table of Contents | Next Page |

Cersosimo Lumber Company has three separate sawmills producing pine and hardwoods in random lengths and widths. Mill No. 1 has a 13" wide double cut headrig and a 10" wide band resaw. Mills No. 2 and 3 each have a 12" wide single cut band headrig with a 10" wide band resaw.

The filing crews recognized that manually leveling band saws is time consuming and highly dependent on the skills of the filer. "The Leveler does nearly all of the leveling, reducing the time spent leveling by 85%," Jones reports. "We still look at every saw on the bench, of course. There is always a place for a good hammerman and we expect to ‘fine tune’ the leveling of the saws as we tension them. Badly damaged saws require some pre-leveling before we put them across the automatic Leveler.

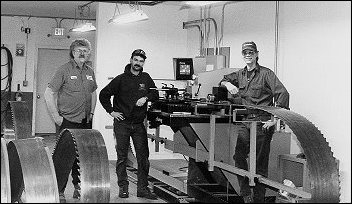

- Left to Right: Stewart Swift, James Phillips, and David Jones standing along side the Armstrong Leveler. Not the touch-screen that gives the filer feedback about the condition of his saw.

"Two major factors in the decision to buy an Armstrong Leveler were the non-contact sensor and the ease with the two sets of leveling rolls were adjusted in unison," David reports. He bought a Leveler for the first mill and ran it for four months. Because of the successful results, he ordered a second Armstrong Leveler for Mill No. 2. Three months after that machine was delivered, Cersosimo ordered yet another Armstrong Leveler for their third sawmill.

David shared with us that "the Leveler is easy to set up. Each saw is usually given two passes. It only takes 10 minutes of operator time and about 40-50 minutes of machine time per saw. We schedule saw changes after four hours, so we can usually put every saw across the Leveler after every run. The saws seem to run better after they have been automatically leveled several times."

The filers give "two thumbs up" to the Armstrong Leveler. "Our filers do not want to work in a filing room without an automatic Leveler," says David.

David Jones is widely respected in the Northeast for his meticulous approach to filing and especially for his success with double cut band saws. David has served as the president of the Northeastern Saw Filers’ Educational Association and has also been invited to speak at both the Maritime and Lakes Erie & Ontario Filer meetings.

"Successful double cut band sawing requires a precisely aligned band saw sharpener. I have used many systems, including at least one that I invented myself a few years ago when I couldn’t buy one that was good enough. The new band saw sharpener alignment system Armstrong just developed is the fastest, easiest and most accurate that I have used."

All six Armstrong band saw sharpeners at Cersosimo have Shape-Up grinding wheel dressing & shaping systems installed. "The Shape-Ups are a God-send when all of our three mills are running two shifts" according to David. "The ShapeUps maintain a uniform gullet shape among all filers on every shifts. They are especially helpful when training new fitters.

|

|

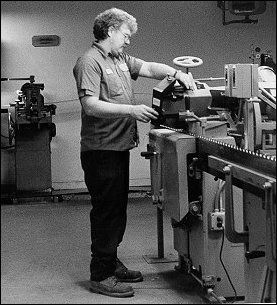

| Dennis Peloquin uses the Armstrong Alignment System on a No. 4 Sharpener with magnetic base dial indicator to center the grinding wheel over the band saw. | Stewart Swift uses the Armstrong Shape-Up to shape and true the grinding wheel on a No. 4 Armstrong sharpener. Note the StrongArm II Power Clamp for better saw control and a sharper cutting edge. |

"We also put air clamps on all the sharpeners. Armstrong’s StrongArm II secures the saw against the faceplate to reduce chatter. The sharpeners just do a better job with these air clamps."

Editor’s Note: The Saw Engineer congratulates Cersosimo Lumber and their filing crew on a fine saw maintenance program. We extend our special thanks to David Jones for his help in preparing this report. Photos courtesy of Rebecca Jones.

| Previous Page | Table of Contents | Next Page |