The Great Performers

The Great Performers |

|

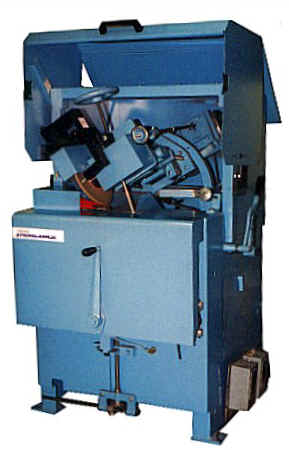

| GREAT PERFORMERS withstand the test of time. Armstrong Band Saw Sharpeners have passed this test and continue to serve saw filers, as they have for more than 50 years. Armstrong machines are prized worldwide for their precision performance, rugged dependability, ease of operation and readily available spare parts. All adjustments are positive and easy to make for many years of fine, trouble-free service. |

| Featuring: |

| Rugged steel and cast-iron construction |

|

| Extra power for heavy grinding |

Large grinding wheel motor (2 HP motors supplied on No. 4 sharpeners equipped for three phase current; 1 HP grinding wheel motors for No. 2 sharpeners or when single phase electrical current is specified for No. 4 sharpeners) and 1 HP action motor for heavy grinding and large saws. |

| Improved grinding wheel arbor assembly |

|

| Multiple, over-sized UHMW cams |

|

| Lower overall costs |

|

| All Armstrong Band Saw Sharpeners come standard with: |

| Enhanced Grinding Wheel Arbor Assembly |

|

| Improved Heavy-Duty Rocker Arm Assembly |

|

| UHMW Cams |

|

| Carbide Faceplate |

|

| Safety Guards |

|

| Adjustable Post Brackets |

|

| See Band Saw Sharpener Options... |

Product Selection Chart |

||||||

| Single Cut Saws | Shake Saws | Single Cut Saws | Double Cut Saws | Single Cut Saws | Double Cut Saws | |

| Model Number | 2 | 2-S | 4 | 4-D | 6 | 6-D |

| Saw Width | 2" to 8" | 1" to 2" | 6" to 14.5" *** | 6" to 14.5" | 8.5" to 16" ** | 8.5" to 16" |

| Tooth Space (Max.) | 2" | 2" | 2.5" | 2.5" | 3.5" | 3.5" |

| Tooth Depth | 1/4"-7/8" | 1/4"-7/8" | 3/8"-1-1/4" | 3/8"-1-1/4 | 1/2"-1-1/2" | 1/2"-1-1/2" |

| Grinding Wheel Size | 10" OD x 1" hole | 10" OD x 1" hole | 12" OD x 1.25"hole | 12" OD x 1.25"hole | 12" OD x 1.25"hole | 12" OD x 1.25"hole |

| Dust Pipe Size | 3" | 3" | 4" | 4" | 4" | 4" |

| Hand Post Brackets | 4 No. 13** | None | 2 No. 16 | 4 No. 16 w/belt | 3 No. 16 | 5 No. 16 w/belt |

| Auto. Post Brackets | 1 No. 14 | None | 1 No. 17 | 1 No. 17 w/belt | 1 No. 17 | 1 No. 17 w/belt |

| Back Feed Guides | None | None | 1 No. 18 * | 2 No. 18 * | 1 No. 18 | 2 No. 18 * |

Copyright(c) 1998-02, Armstrong Mfg. Co., All Rights

Reserved |

new products | publications | equipment |