| All

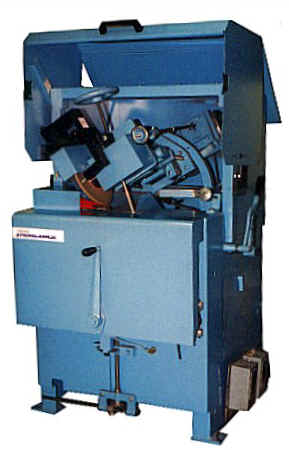

Armstrong Band Saw Sharpeners come standard with: Enhanced Grinding

Wheel Arbor Assembly

Larger motors, one-piece arbor, heavy-duty pillow block bearings

and non-slip, low-vibration poly-V belt drive all contribute to precision grinding for

extremely sharp saws and less chance of burning that can lead to cracks.

Improved Heavy-Duty Rocker Arm

Assembly

These stronger rocker arms increase the life of your grinding wheels and

provide a much smoother grind on your saws. This improved design helps achieve

sharper saws with less chance of gullet cracks.

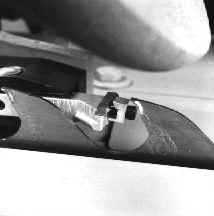

Carbide Faceplate

An oversized, self-cleaning carbide faceplate

is standard on all new band saw sharpeners. Carbide strips are set out from the steel

backing plate for a wear surface that stays clean and can be reground.

UHMW Cams

Armstrong sharpeners are designed to use up to three pairs of

cams, allowing the operator to change tooth designs simply by moving a lever. Each

pair of cams is individually adjustable to enable the filer to produce a precise tooth

shape. One pair of cams is supplied with each sharpener.

Adjustable Post Brackets

For each machine, Armstrong provides both manual and automatic post

brackets. Automatic post brackets raise or lower together with the saw carriage as the saw

height is adjusted.

Safety Guards

Safety guards, covering the pulley, belts and the grinding

wheels, are standard on all sharpeners. |

Featuring:

- Rugged steel and

cast-iron construction

Durability to deliver years of precision performance

- Extra power for heavy

grinding

2 HP grinding wheel motors supplied on No. 4 sharpeners equipped for three phase current;

1 HP grinding wheel motors for No. 2 sharpeners or when single phase electrical current is

specified for No. 4 sharpeners and 1 HP action motors for heavy grinding and large saws.

- Improved grinding wheel arbor

assembly

The grinding wheel arbor is machined from a single bar; there are no pressed joints to

loosen or run out. Tapered roller bearing pillow blocks are now standard on all No. 4

Armstrong sharpeners. Poly-V belt drive to grinding wheel arbor for low vibration, no-slip

grinding.

- Multiple, over-sized UHMW cams

Smoother action, longer wear

and quick, simple change-over betweem tooth shapes.

- Lower overall costs

Precision grinding saves on

grinding wheels, spare parts, and saw consumption!

MANUFACTURING COMPANY

5504 S 11th St, Ridgefield, WA 98642 USA

(503) 228-8381 Fax: (503) 228-8384

www.armstrongblue.com

|