| Previous Page | Table of Contents | Next Page |

PERFORM MONTHLY

1. Check for looseness in the feed finger arm cone screws and bushings. Tighten cone screws snugly, while still allowing the feed finger to fall freely. There should be NO MORE than 1/16" side play.

2. Check grinding wheel arbor and bearing assembly. Inspect the belts, pulleys and arbor for wear or vibration. Bearings should run cool (less than 50�F or 30�C) temperature gain from ambient after 30 minutes of running).

DO NOT OVER GREASE the arbor bearings. Sealed bearings rarely require additional lubrication from that supplied at the factory.

3. Inspect the feed finger and back feed finger for wear. Check especially the leading edge that pushes the saw and the underside that drags up over the saw tooth when the feed finger retracts.

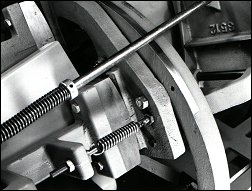

4. Inspect the suspender straps and coil springs on the rocker head. Check the witness marks on the rocker arms for slippage. The coil springs (Part No. 2634-A) should have just enough tension [usually .007" to .012" (.18 mm to .30 mm) between coils when the grinding head is lowered into grinding position], so that the foot of the rocker arm is always in contact with the rocker arm carriage.

5. Inspect faceplate for wear, twisting and proper alignment. Faceplates will wear hollow under the hold down rollers.

| Previous Page | Table of Contents | Next Page |