| Previous Page | Table of Contents | Next Page |

Gulf States Paper: Success on the Cutting Edge

Gulf States Paper equipped and staffed the filing room of their newest sawmill to take advantage of the best technology available. When the Moundville, Alabama mill started in May 1997, the filers were Stellite� tipping their circle saws and side grinding the swaged teeth on their band saws. An Armstrong automatic band saw Leveler was added in early 1998, just before starting the second shift. ShapeUp grinding wheel dresser systems were soon added to the three No. 4 Armstrong band saw sharpeners to help keep both saw performance and file room productivity very high.

|

| Filing lead Ralph Weber collects data on his band saws using Armstrong’s automatic Leveler with optional SawTracker software and a computer. |

Gulf States Paper has a twin 6-ft (1.8 M) Optimil band headrig with chipping heads fed by a sharp chain. Optimil also supplied the 6-ft twin "arc sawing" linebar band resaw. Filing lead Ralph Weber and the six other filers at Gulf States Paper change the saws on all four of the band mills twice each shift in this two-shift mill. All band saws are benched every second run.

| "Without the Leveler, we would need at least one more filer" |

"Without the Armstrong Leveler, we would need at least one more filer to keep up", reports Ralph Weber. "The small ‘knots’ or lumps in the band saws created by chips going around the wheels can be leveled almost completely by the Armstrong Leveler in just two passes. Our Leveler has cut our bench time by 50% and helps us produce a better saw.

|

| Joel Prentice uses the Armstrong SidePro to side grind one of the 38’ 10" (11.8 meter) long swaged tooth band saws. "Side grinding makes smoother lumber and improves recovery." |

"All three of our No. 4 Armstrong band saw sharpeners are equipped with ShapeUp grinding wheel shaping systems. ShapeUps really help us maintain consistent grinding in our two-shift mill. Our sharpeners also have micro-groove (or poly-V) flat belts driving the grinding wheel to reduce vibration and slippage. ShapeUps and micro-groove belts allow us to use 60 grit grinding wheels to produce sharper saws."

| "ShapeUps help us maintain consistent grinding" |

Band saw teeth are side ground on an Armstrong SidePro after swaging and shaping. "We compared side ground teeth to those that were just swaged and shaped: side ground teeth are much sharper. Side grinding the band saws makes smoother lumber and more recovery," Ralph reports. "You can even hear how much quieter these saws are in the cut. Side grinding has to mean less bench work in the file room."

|

| Sid Jacobs operates one of Gulf State Papers’ three No. 4 Armstrong band saw sharpeners. Note the ShapeUp grinding wheel dressing/shaping/truing system attached to the wheel guard. ShapeUps help improve saw performance and file room productivity in this two-shift mill. |

Gulf States’ 8" (200 mm) gang has 22 guided saws with a No. 3 "Retech" spline arbor. The board edger has 3 saws and knives in the top head. All the circular rip saws are Stellite tipped on the Armstrong AUTOTIP.

"The AUTOTIP makes Stellite much easier and faster to tip than carbide," Ralph says. "The rectangular Stellite tips also grind much faster than carbide tips. Our Stellite tipped circular saws run 8 hours on the day shift and ten hours at night.

| "The Leveler has cut our benching time by 50%" |

"It takes us about 20 minutes to change all guides and circle saws in the gang at the end of the first shift. At the end of the second shift, we change all the saws and any guides that are showing wear. Arc sawing puts more wear on the guides than straight line sawing," Ralph explains. "It is very important to pay close attention to guide wear. We have .0025" guide clearance now, but expect to reduce that to .002" soon."

|

| James Peebles uses a TrueSizer to side grind a carbide trim saw here. The same TrueSizer is easily changed to side grind the Stellite tipped gang and board edger saws. |

Ralph Weber started filing in 1971 at a saw shop near where Gulf States Paper now has their sawmill. He worked for ten years as a millwright and relief sawyer at a small hardwood mill before returning full time to filing when Gulf States Paper opened their big mill. "I took over the head filing job when Blaine Alexander, the former head filer, joined his father as a partner in Tuscaloosa Saw Works," Ralph reports. "Blaine got our program off to a great start and continues to provide our team with technical support."

|

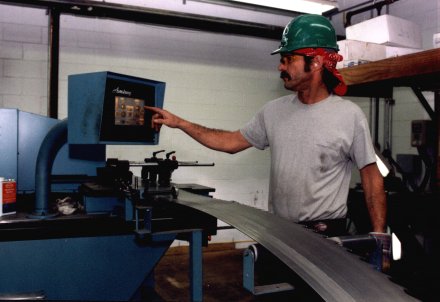

| Bob Rowland uses the touch screen to operate the Armstrong automatic band saw Leveler. Filing lead Ralph Weber reports "We would need at least one more filer to keep up if we didn’t have the Armstrong Leveler." |

Armstrong salutes the filing crew at Gulf States Paper on their success at Moundville. Our special thanks to Ralph Weber for his help in preparing this article and to Gulf State Paper’s Dave Gardner for taking the photographs.

| Previous Page | Table of Contents | Next Page |