| Previous Page | Table of Contents |

Filing Room Upgrades Improve Quality, Efficiency of Hardwood Mill

The quest for quality and efficiency can pay big dividends, even for newer sawmills, as demonstrated by Paris Sawmill North, of Elmira, Michigan. Continuing investment in the filing room has already improved saw performance enough to increase volume and reduce kerfs and target sizes and customers really like the improvements in product quality that have been realized.

Paris Sawmill, Inc., established in 1985, opened their North Division Sawmill in Elmira in 1994. They produce 28,000 board feet (67 cubic meters) of mostly Hard Maple lumber in a single shift each day. Red Oak, Ash, Basswood, Soft Maple and Cherry are also sawn. Paris North exports about 15% of its production.

The mill consists of a 7 foot (2.1M) head rig and a 7 foot line bar running 12" (305mm) X .078" (1.98mm) band saws swaged, shaped and side-ground to .128" (3.25mm) kerf. Saws are run for four hours and are reswaged after two runs. The saws are maintained with two No. 4 Armstrong band saw sharpeners, SidePro side grinder, Armstrong band saw Leveler and stretcher roll.

- Ernie Jones punches up data for Paris North’s head rig band saw on the Leveler’s "touch" screen. "The Leveler helps me do the best job," Ernie says.

Steady improvements in the filing room have been made since the mill opened. The older band saw sharpeners were rebuilt with new wear parts, including heavy duty rocker arms. ShapeUp grinding wheel dressers and resinoid ceramic grinding wheels were also installed. The Leveler was added in 1996 and the SidePro horizontal dual side grinder in 1997. Most recently, safety hoods have been installed on the band saw sharpeners.

All improvements have resulted in time savings for the two saw filers. Ernie Jones maintains the head rig saws and Jeff Makareqicz files the band resaws. Both Ernie and Jeff learned to file band saws at this mill and now have two years experience.

Ernie uses a "frost tooth" on the head rig year round, but with less kerf in frozen logs. Jeff doesn’t change the resaws in the winter because, "the side-ground saws cut as smooth as glass in the winter."

Jeff and Ernie spend a lot less time at the bench since the Leveler was installed. The resaws "run quieter and smoother, with more uniform tension and less hammering," according to Jeff. Ernie reports, "the head saws run more true, cooler and with less kerf."

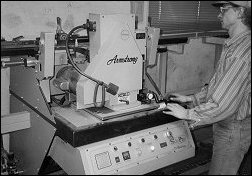

- Jeff Makarewicz side grinds Paris North’s band resaw on the SidePro horizontal dual side grinder. The side-ground saws cut lumber "smooth as glass" in the winter.

"The Leveler and SidePro fully met our expectations," according to Mill Manager, Bill Lenau. "Especially in time saved and much-improved saw performance. We have increased our feed rates, recovery and the quality of the lumber." Kerf was reduced .010" (.25mm) and target size another .010".

Bill Lenau and the filers looked at various brands of levelers and side grinders. "We talked to the owners and filers using the equipment," Bill said. "We decided Armstrong was the best engineered and easiest to operate. Ernie and Jeff didn’t need much training to level and side grind saws on the Armstrong machines."

Bill concludes, "We believe this new equipment has helped the filers do a professional job maintaining a superior quality product for our customers while improving mill efficiency."

The Saw Engineer commends Paris Sawmill North on their success and extends a special thanks to Ben Mroz of Menominee Saw & Supply for taking the photographs.

| Previous Page | Table of Contents |