|

Click here to print datasheet |

|

The circle saw stretcher roll's ability to tension and level saws with great speed and

efficiency is a major advantage in busy filing rooms. Armstrong stretcher rolls

uniformly tension saws as much as 10 to 20 times faster than is possible with a hammer and

anvil, and with far less effort. These machines are simple to operate, heavy duty in

design and perform well on even the heaviest gauge saws. |

In addition to the speed, Armstrong stretcher rolls provide greater uniformity and control

over the tensioning process. Both the 3-10-C and 3-60-C gently roll the same tension

all around the saw. |

|

|

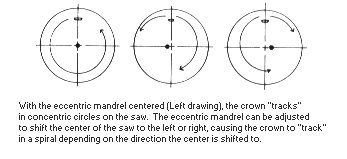

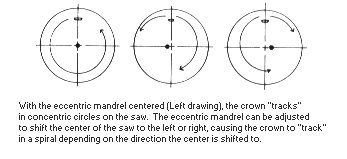

| Eccentric Mandrel: |

| The eccentric mandrel on the stretcher roll can be adjusted so that the

crown travels in concentric rings on the saw or in a spiral. When placed

perpendicular to the radius of the saw, the rings will be concentric. Moving the

eccentric mandrel slightly off-center will crate a spiraling of the crown on the saw. |

|

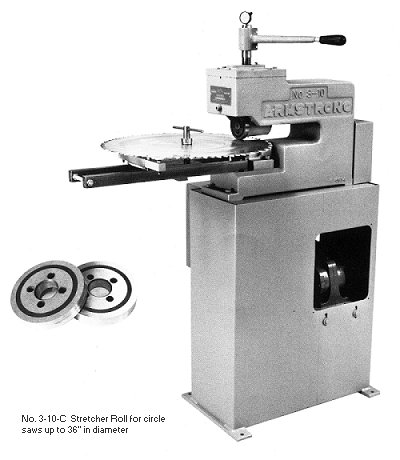

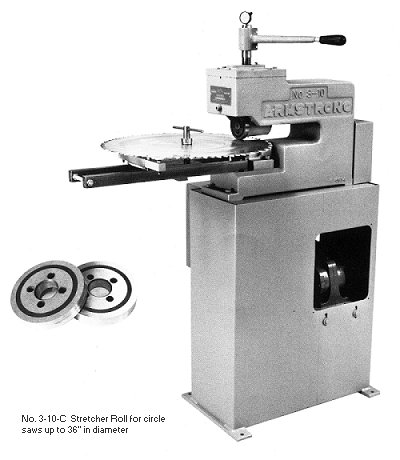

| Two Models Available: |

| Depending on your requirements, Armstrong offers two stretcher roll

models. the 3-10-C accommodates saws up to 36" in diameter. When tensioning a

36" saw, the 3-10-C rolls to within 7" of the center of the saw. On

smaller saws, operators are able to tension even closer to the eye. |

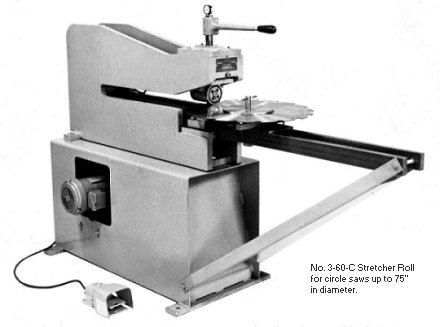

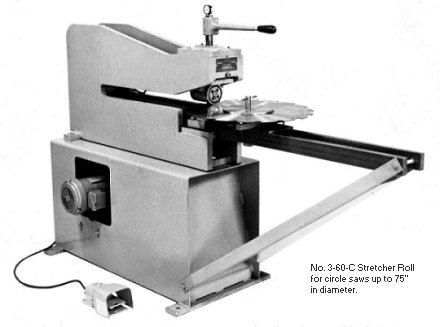

| For saws up to 75" in diameter, the 3-60-C is ideal. This

larger model tensions saws to within 9-1/2" of the center of a 75" saw or in

even closer on smaller saws. |

| Both models come complete with a 1 HP motor for standard alternating

current, magnetic switch, convenient foot pedal and a standard four-step centering

bushing. |

| 3-10-C and 3-60-C

Features |

| SPEED: |

| Filers can perform the task of tensioning saws much quicker than by

hammering - as much as 10 to 20 times faster. |

| UNIFORMITY: |

| Stretcher rolls tension saws smoothly and uniformly from the center of

the saw to the gullet line. |

| HAMMER MARKS ELIMINATED: |

| Eliminating hammer marks helps to ensure top performance from even thin

kerf saws, such as those used on modern guided multi-saw rip machines. |

| HEAVY-DUTY BUILD: |

| The sturdy cast-iron or steel frame, steel floor stand and heavy-duty

anti-friction bearings assure years of trouble-free service. A 1 HP motor provides power

to tension even the heaviest gauge saw. |

| CONVENIENCE: |

| The foot pedal control starts and stops the rolls. The saw quickly

adjusts in and out on steel rails for precise positioning of the rolls. |

| Options and

Accessories |

| STEPPED SAW CENTERING

BUSHING: |

| Each machine comes with a stepped bushing to handle saws with center

holes of 1", 1-1/8", 1-1/4", 1-38". Single step bushings for

larger eyes are available at extra cost. A special mandrel is also available for saw

bores down to 1/2". |

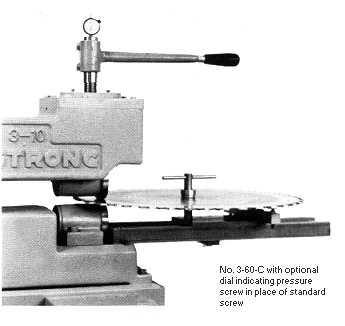

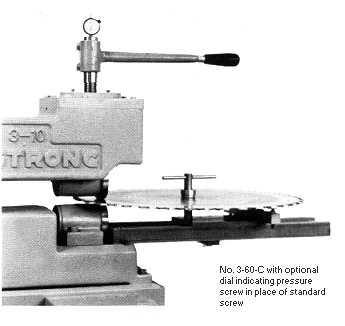

| DIAL INDICATING PRESSURE

SCREW: |

| Completely interchangeable with the standard screw, the optional dial

indicating pressure screw shows the amount of pressure being applied to the saw directly

on the dial. This option is very useful in maintaining and repeating the correct

pressure and in training new filers. |

|

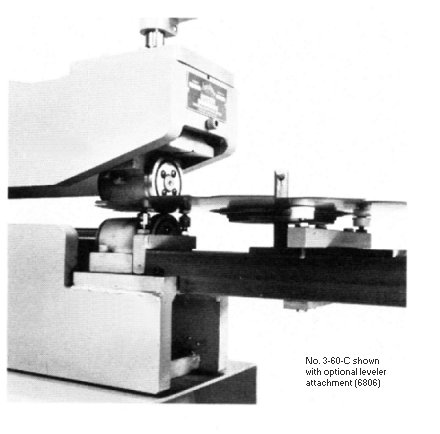

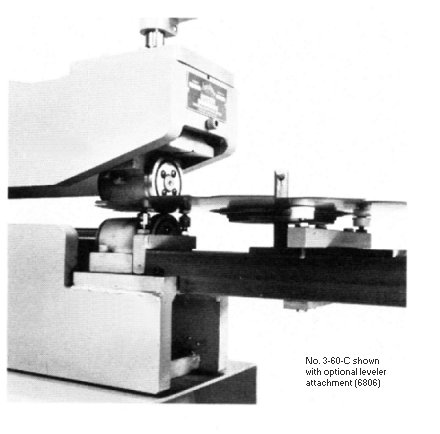

| LEVELING ATTACHMENT: |

| The hardened and crowned rollers are set to the desired height and the

tensioning rolls pull the saw through without adding tension. The optional

attachment is quickly installed and removed and is used for both standard circle and Strob

saws. |

|

| STRETCHER ROLLS: |

| The standard tensioning rolls included with each machine are ground to a

4" crown. This crown works very well on a wide range of circle saws. |

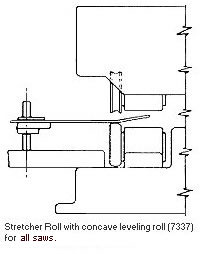

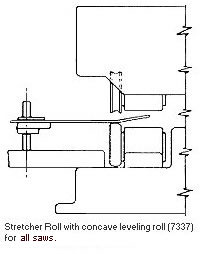

| LEVELING ROLLS: |

| A concave leveling roll is available. Armstrong's part

number 7337 is a fully concave roll, ideal for all saws. |

|

| SPECIFICATIONS:

| |

3-10-C |

3-60-C |

| CAPACITY: |

36" diameter saws, tensioning to within 7" of saw center (92 cm

saws, tensioning to within 18cm of saw center) |

75" diameter saws, tensioning to within 9-1/2" of saw center

(190 cm saws, tensioning to within 25 cm of saw center) |

| MAX. GAUGE: |

4 gauge (.238" or 6.04cm)* |

4 gauge (.238" or 6.04cm)* |

| STANDARD FEED: |

40 feet/minute (12 meters/minute) |

40 feet/minute (12 meters/minute) |

| MOTOR: |

1 HP gearhead (.75 kilowatts) |

1 HP gearhead (.75 kilowatts) |

| HEIGHT OVERALL: |

58" (147.3 cm) |

54" (137.2 cm) |

| FLOOR SPACE: |

21" X 41" (53.3 cm X 104.1 cm) |

24" X 79-1/2" (61 cm X 202 cm) |

| WEIGHT, TRUCK CRATE: |

700 lbs. (320 kg) |

1300 lbs. (600 kg) |

| WEIGHT, OCEAN CRATE: |

800 lbs. (370 kg) |

1400 lbs. (650 kg) |

| CUBIC FEET: |

53 cu. ft. (1.5 cu. meters) |

72 cu. ft. (2 cu. meters) |

* With standard 4" radius crown. Even heavier plates, sometimes up to 5/8"

(16 mm) may be rolled effectively in certain circumstances with rolls ground to a sharper

crown. Please provide the Armstrong factory with details of your saws for a

recommendation. |

|

ORDERING INFORMATION: |

Prices for circular saw stretcher rolls include gearmotor and starter for

standard alternating current, foot switch with low voltage control, eccentric mandrel,

steel floor base and one 4-step bushing for saw eyes 1", 1-1/8", 1-1/4",

and 1-3/8".

|

| PART NUMBER |

DESCRIPTION |

| 6929 |

Single step bushings for large saw eyes |

| 6806 |

Leveler attachment |

| 7337 |

Leveling roll concave |

| 6934 |

Tensioning rolls (4" radius, standard) |

| 8042 |

Dial indication pressure screw |

|