|

Hull-Oakes Lumber, one of the last steam-powered sawmills in the United States, lies at the end of a gravel road, at the base of the Oregon Coast Mountains. Even against the green back drop of the tree-covered mountains, the wood |

| boilers burn so clean that it is usually difficult to see the

smoke.

|

|

|

| An overview of the mill taken from above the edger. The mill is largely open to the air on three sides. |

The mill was built at the end of the power line where there was just enough electricity to

run lights and small motors, but not enough for a sawmill. Today, 60 years later, it is

still operating that way.

Wood waste from the mill is burned to heat the black, cast iron boilers. Steam from the boilers is piped to a steam engine beneath the mill, which turns a flat belt pulley. More belts and pulleys transfer the power to a 9-foot (2.7 meter) headrig band mill, carriage and edger.

|

| The mill is shown with the green chain on the far left. No visible

smoke escapes the two smokestacks for the wood-fired boilers that power the headrig band

mill, carriage and edger.

|

|

| The ratchet setter rides the carriage and positions the log according to hand signals from the sawyer as the log is broken down on the headrig. The setter walks to the front of the carriage to assist the off-bearer by holding the front of the slab against the log with a picaroon. |

The mill, which cuts about 18 million board feet (43,000 cubic meters) of Douglas fir a

year, specializes in cutting big logs. In 1986 they sawed a single log into six 85 foot

long X 34" wide X 4" thick (26 meters X 860 mm X 100 mm) picnic tabletops, one

of which was made into a table for Bellfountain Park, just down the road from the sawmill.

The boilers are fired up at midnight to build up a head of steam prior to the start of the single shift mill. Although it is open on two sides, the sawmill never closes because of cold weather. The water lines are drained at the end of the shift whenever frost threatens.

|

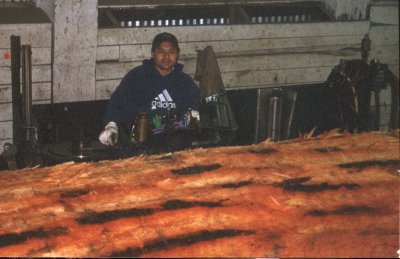

| Hull-Oakes specializes in big lumber, such as these 85' long x

34" wide (26 meters x 860 mm) picnic tabletops. One of these boards was made into a

single picnic table (with seating for 80 people) for the company park, located on the

Alsea River, just down the road from the sawmill.

|

|

| Hull-Oakes saws big logs, many over 48" in diameter. This photo was taken while standing next to the sawyer, who sits in an open-air saw box between the log deck and the band mill. |

Head Filer Tom Coggswell runs the all-Armstrong filing room. Tom uses a No. 6 Armstrong

sharpener for the headrig bands, and a No. 4 sharpener for the electric-powered vertical

band resaw. Solid tooth trim saws are sharpened on a No. 16 Armstrong sharpener that is

nearly as old as the sawmill.

Thousands of people from around the world tour the mill every year. Tom will sometimes lead the tour (free, but an appointment is recommended), especially when filers are visiting.

|

| Pictured with a 24" x 26" x 20 ft (600 mm x 660 mm x 6

meter) Douglas fir beam in Hull-Oakes sorting yard (left to right): Armstrong General

Manager John Wilson, Simonds President Ray Martino and Hull-Oakes Head Filer Tom

Coggswell. Armstrong is a wholly owned subsidiary of Simonds Industries.

|

|

| Head Filer Tom Coggswell stands in front of the band headrig at Hull-Oakes. |

At the age of 87, Ralph Hull is still active today. He and his grandson Todd Nystrom are responsible for the day to day operation. For an appointment, telephone 541/424-3112 or fax 541/424-3012.

|

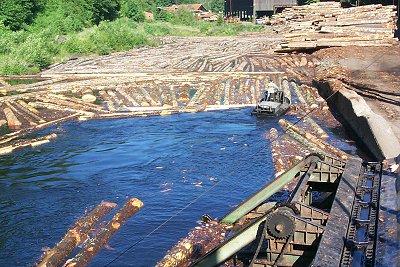

| This sawmill log pond was established around 1919. Originally, the pond

man walked the logs using a pikepole to arrange the logs for entry into the sawmill.

Currently a pond boat is being used and today the driver is enjoying the sunshine. Not a

good job when it is raining.

|

|

| Head Filer Tomy Coggswell with Paul Benoit and Susan Caselli from Simonds

Industries.

|

|

| Operator with large inserted-tooth cut-off saw used to cut these large cants to a specific length. |

Click here for another article on Hull Oakes Lumber Co. from OPB |