smaller lumber each day at the Kure City, Japan sawmill complex of Chugoku Lumber Company. Sawing North American and New Zealand Douglas Fir, Chugoku is the largest producer of these materials used for construction of traditional Japanese homes.

The original sawmill at Kure City, about 20 miles (30 kin) from Hiroshima, began as a chip plant in 1953, supplying chips to a nearby pulp mill Later, they began producing posts and small lumber from Russian logs. In 1967, a second sawmill was built at Iwakuni, 37 miles (60 kin) west of Kure. Chugoku Lumber president Mr. Yasuyuki Horikawa manages the company, assisted by his brothers Mr. Shigeyuki Horikawa and Mr. Noriyuki Horikawa, who also manages the Iwakuni mill.

“170 bandsaws are returned to two filing rooms daily.”

When the source of Russian logs became unreliable in the late 1970’s, Chugoku began sawing Douglas Fir from the west coast of North America. The larger band mills required to saw these big logs were installed and the wide band saws were sharpened on grinders made in Japan. Designed for small band saws, the Japanese-made sharpeners did not handle the larger saws very well.

In 1990, an extensive project was begun to update the mill complex at Kure, including the two filing rooms which service the many band and circular saws. Every aspect of the mill has been evaluated for potential increases in production and efficiency. Improvements in the mill and filing rooms, staff training and the addition of a second shift in part of the complex have allowed Chugoku to increase production by 60% since 1992.

“We wanted to increase our cutting speed, make the sawn face smoother and reduce the kerf,” according to Shigeharu Deguchi, Saw Filing Manager. Over the four years that followed, two No. 4 Armstrong Sharpeners, one Armstrong PRO-Filer, one No. 85 Armstrong AUTOTIP, two No.90 Armstrong EQUALIZER dual side grinders, two Armstrong TrueSizer dual side grinders, two No. 81 Armstrong Band Saw Benches and two No. 4 Armstrong Stretcher Rolls and two Simonds band saw 1evellers were installed.

“We chose Armstrong equipment because your reputation has been established for a long time and your machines are strongly built,” reports Mr. Shigeyuki Horikawa, who is in charge of specifying which new equipment to buy. He and his saw filers visited the Armstrong factory to inspect the machines before placing each order.

Band saws run for four hours and are resharpened 12-13 times between Stellite tippings Stellite tipping had previously been fle by hand. Use of the AUTOTIP has saved many hours of work and fewer saw teeth are lost, resulting in fewer saw changes. “Overall, about 20% of the total work has been saved, lumber is smoother and production is getting larger and larger,” according to Shigeharu Deguchi.

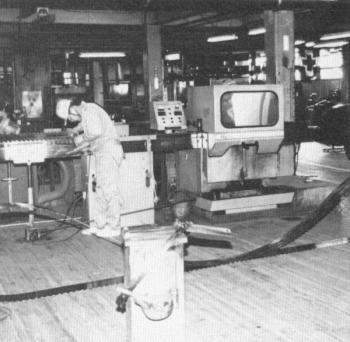

The mill complex includes one 6’ double cut, two 5’ twin head rigs, two 5’ “center cut,” three double cut and 27 horizontal resaws. About 1/2 of these band sawing centers and both filing rooms operate two shifts. Altogether 170 bandsaws are returned to the two filing rooms each day.

In all, there are 24 saw filers working under k direction of Saw Filing Manager Shigeharu ‘ruschi and Group Leaders Shinji Tanabe, Mitsuaki Hotehama, Shoichi Onomura and Isamu Itada. Great attention is paid to staff training. A filer’s manual was compiled and is kept on hand for quick reference. Thirteen filers have passed the second degree state examination for saw filers. Six filers have traveled to the U.S. and Canada to train at the Armstrong factory and visit sawmills and trade shows to learn more about new filing technology.

Note: Congratulations and thanks to all the people at Chugoku Lumber for sharing their story with us. The editors especially appreciate the contributions of photographer Yuji Nakamura and Superintendent Masahiro Orikawa.

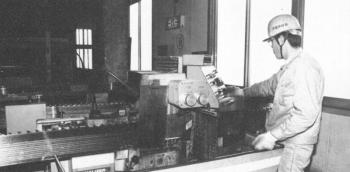

Katsuhiro Utsunomia side grinds a Stellite tipped band saw on one of two No.90 Armstrong EQUALIZERS. With their EQUALIZERS, Chugoku Lumber has reduced the kerf and produces smoother lumber on their 45 bandmills.

• Clearer, larger, full-color photographs can be used.

• Ability to post new material at any time rather than limited to just 16 small pages twice a year.

• Archived past issues can be accessed at any time.

• Filers and sawmillers can access the website at any time from anywhere in the world. You need never again miss another issue even if you’ve moved or changed jobs.

• Hot links can take readers to related websites.

• Search function lets visitors to our site quickly find articles on the topics that interest them from the nearly 1000 pages now available.

• Access to rapidly changing postings, such as the list of second-hand machines that we have available.

• Complete listing of all the Saw Filer Educational Associations, including E-mail addresses and conference agendas.

• Interactive functions, such as the brand new band saw feed rate calculator that just opened.

Technical articles and features of interest to saw filers are being added to our website nearly every month. While only a minority of sawmills presently have access to the Internet from the filing room, nearly every sawmiller in the world can “log on” to the Internet. Gateways are available from the sawmiil office, from home, from the local libraries, from nearby hotels that cater to business travelers, or from the many Internet cafes that have opened the last few years.

If you have not yet visited Armstrong’s website, you are invited do to so now. The many filers who have already been to our site are invited back to see all the recent enhancements. From now on, you will only find the saw filing articles from the Saw Engineer at www.armstrongblue.com. You will also find much, much more.