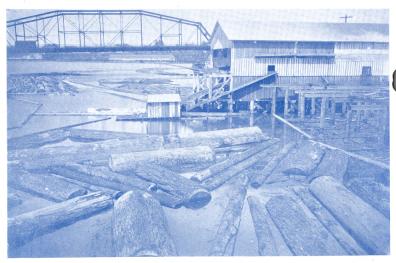

| EP traveled to Oregon in 1904 to work as the head filer at the Standard

Box and Lumber Co., near the East end of the old Burnside Bridge in Portland,

Oregon. His son, Harry worked at the mill alongside his father. Prompted

by requests from filer friends for better tools, EP set up his drawing

board in the corner of the filing room and did some office work in a spare

room at his home. |

|

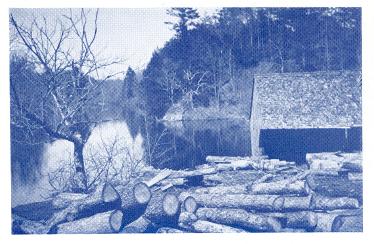

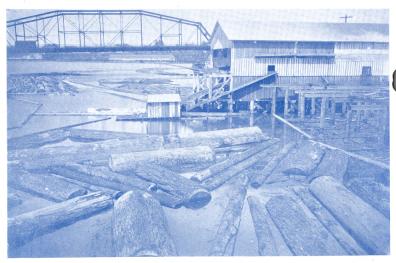

| The sawmill of the Standard Box and Lumber

Company was located near the East end of the old Burnside Bridge. E.P. balanced

his time between head filer at the mill and designing and building tools

for other filers. |

|

|

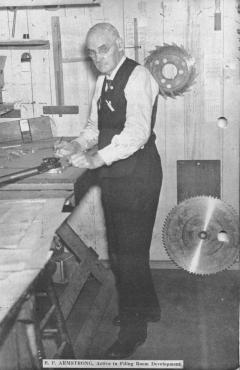

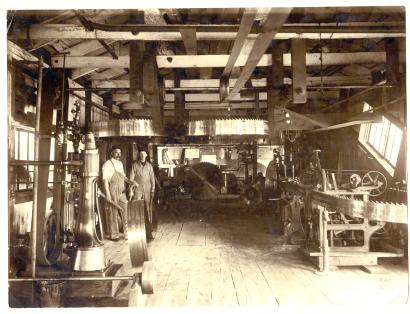

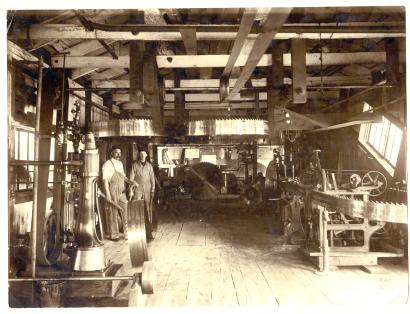

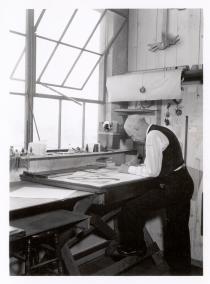

| E.P. Armstrong (at left) in the file

room at Standard Box and Lumber Company in Portland, Oregon. Note the flat

belt running overhead that powered the machinery in the file room. |

His growing sideline business consumed more and more of his time, so

he went to the mill owner and asked if his son Harry could take over as

head filer. EP assured him that he would continue to work in the saw shop

and would personally inspect every saw. EP shrewdly negotiated full head

filer pay for his son (and presumably EP also received some compensation,

too).

The mill owner asked how old the son was. EP proudly told him that Harry

was 14, fully capable of doing a man's work every day. The mill owner

recognized that the Armstrong's were the best filing team he had ever

had. His saws ran better and downtime was never caused by poorly maintained

saws. So he agreed and EP began to devote his full attention to his growing

business, while Harry shouldered a man's job at 14.

EP opened a small jobbing machine shop near the sawmill and named it

Armstrong Mfg. Co. Many trips were being made between the mill and the

shop. Turning out machinery in the shop required a considerable amount

of engineering and design work. The demands on EP's time led him to the

decision to discontinue the job shop and devote his full time to the manufacture

of saw tools. Later, sharpeners, stretcher rolls, etc. added to the line.

|

|

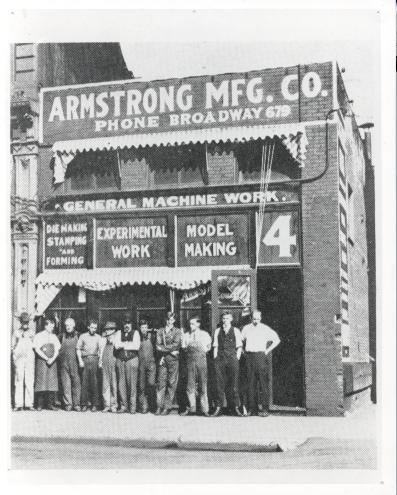

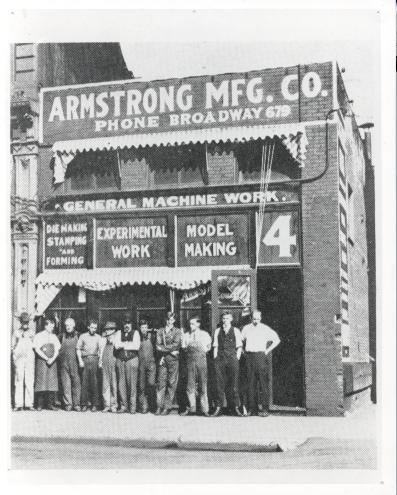

| The first factory of the Armstrong Manufacturing Company

general machine works was located in downtown Portland. They proudly advertised

their 5 digit phone number BR-679. All phones in Portland require 10-digit

dailing today. |

All tools and spare parts carried the trademarked ringed "A"

guarantee, which signified that they were genuine Armstrong parts made

for maximum wear, proper fit and backed by a service promise. |

|

The business grew to the point that both EP and Harry needed to work

full time making saw tools, so Harry left the Standard Box & Lumber

Company, when the mill burned in 1915, to join his father in the business.

They delivered swages, shapers and spare parts to filers locally on foot,

walking to the 30 sawmills that lined the Willamette river just within

the city limits of Portland.

In 1928, Harry moved his family from Portland, Oregon to Longview, Washington

to take the head filer job at Weyerhaeuser's Mill 3, one of the most prestigious

filing jobs on the West Coast. He transferred to Mill 2 in 1942 and retired

in 1960, after 32 years with Weyerhaeuser. Harry died in 1982 at the age

of 88. Harry's son, Don, also became active in the industry. See the Saw

Engineer article featured in the history of Armstrong Mfg.

|

|

|

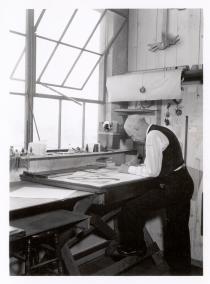

Left: E.P. busily at

work at his drafting table, designing tools and parts.

Right: Son Lloyd spent most of his time managing the day-to-day business

of the company. |

|

Edward's son, Lloyd, joined his father at the company in 1925. Lloyd

had spent many years in the filing room, gathering the knowledge about

saws that his father insisted both sons know. He became President of the

company after his father passed away in 1942.

Lloyd served as President and Chairman of the corporation for many years

until he retired in 1975. Lloyd moved to New Mexico where he lived until

his death in 1986 at age 88.

Edward P. Armstrong will well be remembered for his dedication and influence

to saw filers and the filing trade. He was always striving to improve

and advance, which required a large measure of initiative, courage, and

faith in himself and loyalty to his associates.

His unswerving perseverance to provide the best saw filing tools available

was the foundation of Armstrong Manufacturing Company and remains central

to our continuing mission.

|

|

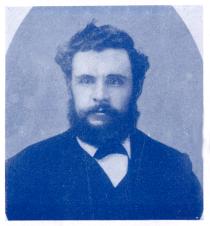

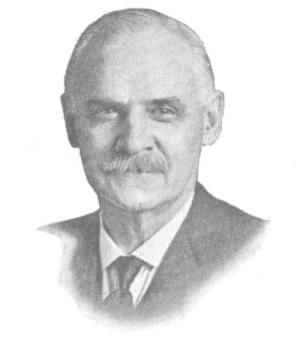

Edward P. Armstrong (1865-1942)

Founder of Armstrong Mfg. Co. |

| |

| |