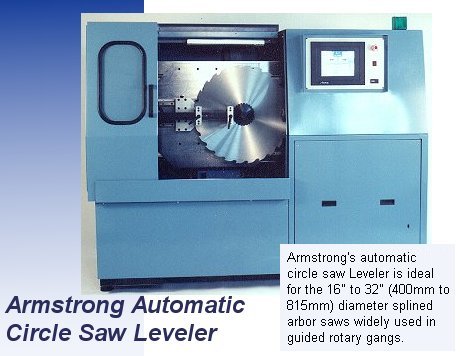

FEATURES:

- One button leveling: just load the saw, close the door and

press one button (not available in metric).

- Three stages of factory set engagements for each plate

thickness apply the correct pressure for small, medium and severe bumps. The head filer

can quickly override these digital settings at any time: there are no mechanical stops to

get out of adjustment.

- Saws "float" on the centering hub. The eye does not

distort the flatness of the saw plate as can happen when the saw eye is clamped.

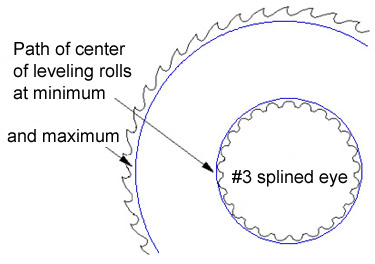

- Levels closer to the eye than any other machine. The leveling

rolls reach inside the large diameter of #3 and larger splined arbor saws.

- Works imperfections as small as .0006" (six tenths

of a thousandth of an inch).

- Inspects and levels 100% of the saw plate in two passes. Other

machines often skip over half the saw surface, working a few concentric rings across the

saw, trying to achieve the same speed as Armstrong.

|

- Operator can select a one button "map and attack"

option to work the biggest bumps first before automatically continuing to regular leveling

mode.

- Built in memory recalls exactly how the head filer wants the

saw to be leveled and stores those settings for up to six different saws to minimize

set-up when switching from one saw type to another. Because just the right amount of

pressure is applied to each saw type, every saw is leveled perfectly.

- Color graph stores the results of up to three passes so the

operator can see the improvements made to the saw.

- Vertical orientation eliminates the effects of gravity for a

more perfectly leveled saw.

|