Armstrong

Introduces the VariSharp CNC band saw sharpener

Armstrong’s VariSharp CNC band saw

sharpener features a two-axis CNC system to grind virtually all band saw tooth patterns

used by sawmills today. Touchscreen control, industrial-grade Pentium computer, and

brushless servo-driven ball screws replace the two-cam system previously used. With

VariSharp, it's possible to sharpen saws you are using today, while you design those you

will use tomorrow.

MANUFACTURING COMPANY

5504 S 11th St, Ridgefield, WA 98642, USA

(503) 228-8381 Fax: (503) 228-8384

www.armstrongblue.com

|

|

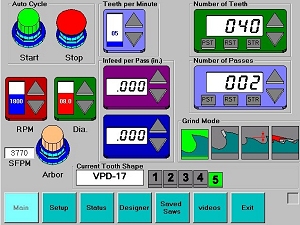

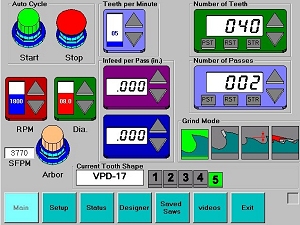

Grinding parameters, including on/off the

face, gullet depth, and number of grinding passes can be controlled by operator inputs on

the touchscreen or manually as on a standard No. 4 sharpener. Grinding wheel rpm and teeth

per minute are also touchscreen controlled. A powerful 2-hp grinding wheel motor and

variable frequency drive provide optimum grinding performance. |

|

Armstrong

VariSharp CNC Band Saw Sharpener

|

Features:

- Pentium 233 MMX PC control.

- Brushless servo system for long life and precision grinding

control.

- Touchscreen control for easy operation and feedback about the

sharpener, such as number of teeth sharpened per minute, and a picture of the tooth.

- On-board Armstrong tooth library with over 300 standard, VP,

and VPD tooth patterns.

- New teeth or VPD patterns can be drawn or modified on screen

and saved to the tooth library.

- DXF (Drawing Interchange File) export capability: the operator

can download tooth parameters to a floppy disk that saw makers can use to produce the

exact tooth pattern the operator has designed on the console.

- Larger 2 hp (1.3 kW) grinding wheel motor with grinding wheel

speed control via the touchscreen.

- Constant power supply for the PC to minimize machine

interruption.

- Complete control of machine speed. The operator can change the

number of teeth sharpened per minute. On a freshly tipped Cobalt Chromium Alloy saw, it is possible to

slowly grind the face and top of each Cobalt Chromium Alloy tip while quickly skipping over the rest of

the tooth on the first grinding pass.

- Capacity to sharpen conventional constant pitch saws or

repeating segments of teeth with variable pitch or depth, with up to ten teeth per

segment.

- Air back feed units and StrongArm II power clamp are precisely

timed via computer outputs.

- Step-by-step instructions will be available on demand

through the touchscreen console to make it easy to train new operators. A detailed

operator’s manual covering installation and machine operation is provided.

- Accommodates toothspace of 1.250" (32 mm) to 3.00"

(76mm)

|

|

|

The on-board Armstrong tooth

library includes over 300 standard, variable pitch (VP) and variable pitch and depth (VPD)

tooth patterns available on the touchscreen. Operators can view, modify, and save a single

tooth, or a VP/VPD pattern with up to ten teeth in the segment. The tooth library will

hold an unlimited number of tooth patterns. When ordering saws, saved patterns can be

supplied from the library to the saw manufacturer for use in producing the exact tooth

pattern. |

| Machine

specifications for a VariSharp are the same as for a conventional No. 4 Armstrong band saw

sharpener. All No. 4 sharpener options are available for the VariSharp. Sidewinder feed

finger, StrongArm power gate, and ShapeUp grinding wheel dressing system are required.

|

|

MANUFACTURING COMPANY

5504 S 11th St Ridgefield, WA 98642

(503) 228-8381 Fax: (503) 228-8384

www.armstrongblue.com

|

|

|