Levels from the Inside of Saw

The non-contact sensor activates the leveling rolls on imperfections as small as

.001” (.025 mm). This sensor is not affected by vibration in the file room,

surface roughness or even pitch on the saws. It levels saws much more accurately

than machines that use a dial indicator.

The sensor detects imperfections from the

inside of the saw. Saws are flatter where it really counts: against the guides and

on the wheels. Any variation in plate thickness due to wear or the butt weld is

leveled to the outside.

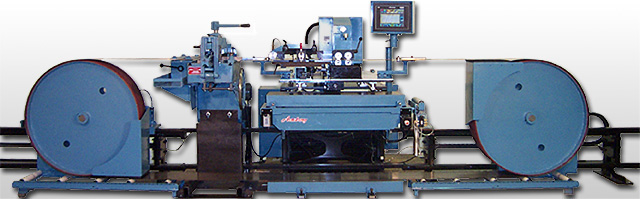

Steel Wheels Stretch and

Drive Saw

Saws are leveled on the semi-automatic bench with Armstrong’s proven super duty band

saw Leveler. Steel wheels with a special coating to protect the saw apply 2,000 lbs.

of strain to the band saw. This strain makes it possible to quickly and accurately level

even large saws or saws with extra tension. One of these 42” diameter steel wheels

drives the saw for positive saw control.There is no tendency for saws to slip, even when

the saws are wet or oily.

MANUFACTURING COMPANY

5504 S 11th St, Ridgefield, WA 98642

(503) 228-8381 Fax: (503) 228-8384

www.armstrongblue.com

|

Touch Screen Control

Easy to use touchscreen shows the operator just what to do and reports information about

the saw. All adjustments are made on the screen. Operators do not have to

crawl behind the machine with wrenches to make adjustments, as on European machines.

Set-ups are fast, accurate and stored in the built-in memory for instant recall.

Made in USA

Rugged North American components are designed for the larger saws used on American and

Canadian bandmills. Spare parts and service readily available through your local

independent Armstrong Stocking Distributor/Service Center.

|

Filers can quickly adjust

the tension and back using the conventional stretcher roll and two full sized leveling

blocks. A motor pushes the automatic leveler back out of the way while raising

the upper leveling block into working position. The change from leveling to

tensioning takes just one minute. |

|

An air cylinder lifts the

saw for fast and consistent tension checks. Both leveling

blocks are positioned with large adjusting screws so they

are precisely aligned with the band saw.

An air cylinder lifts the

saw for fast and consistent tension checks. Both leveling

blocks are positioned with large adjusting screws so they

are precisely aligned with the band saw.  A large motor and clutch drive

one of the 42" diameter steel wheels to maintain a constant

speed of 50 ft per minute during leveling. The motor

works through a clutch that disengages this saw drive mechanism

when the stretcher roll is being used.

A large motor and clutch drive

one of the 42" diameter steel wheels to maintain a constant

speed of 50 ft per minute during leveling. The motor

works through a clutch that disengages this saw drive mechanism

when the stretcher roll is being used. An optional welding clamp

stand permits welding at the workstation. All the benching

functions can be performed at this highly productive workstation.

An optional welding clamp

stand permits welding at the workstation. All the benching

functions can be performed at this highly productive workstation.